| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Zhengtong

Model Number : B20-B505

Place of Origin : Zhengzhou

MOQ : 100KGS

Price : Negotiable

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 250mts monthly

Delivery Time : 3-5 days after order confirmed

Packaging Details : 25kg barrel+pallet or 2*12.5kg barrel+carton+pallet

Commodity : Ceramic Blasting Media

Product Name : Ceramic Beads Blasting

Color : White

Bulk Density : 2.3g/cm3

Hardness : 700HV

Sphericity : ≥85%

Shape : Round Solid Beads

Specification : B20,B30,B40,B60,B80,B100,B120,B150,B170,B205,B400,B505

Certification : N/A

ZrO2 60-66% 700HV Hardness Ceramic Bead Blasting Media Zirconia Sand B40 B60 for Mold Cleaning

1. Product Description of Ceramic Beads

Ceramic beads is one clean blasting media,it is also called as ceramic blasting media.

If you are looking for one blasting media to replace glass beads,also achieve to smooth,bright blasting effect with lower

toughness,then ceramic beads is the best choice for you.

Compared with glass beads,ceramic beads has lower breakdown rate,it will provide one bright and clean blasting environment,ensure the workers to escape from the hidden dangers of silicosis,it is good for the worker’s health.

Ceramic beads also has lower cost for solid-waste treatment also due to its lower breakdown rate,then little dust

generated in the whole blasting process.

So ceramic beads is one clean and economic blasting media.

2. Main Technical Data of Ceramic Beads

| Chemical Index | ZrO2 60-66% SiO2 25-30% Al2O3 7-13% | |

| Physical Index | Vickers Hardness ≥700 HV Bulk Density≥2.3g/cm3 True Gravity: 3.85g/cm3 Process: Melting | |

| Particle Size | B20: 0.600-0.850mm | B120: 0.063-0.125mm |

| B30: 0.425-0.600mm | B150: 0.053-0.106mm | |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm | |

| B60: 0.150-0.300mm | B205: 0.000-0.063mm | |

| B80: 0.125-0.212mm | B400: 0.030-0.063mm | |

| B100: 0.106-0.180mm | B505: 0.000-0.030mm | |

| Remark: Special specification can be customized | ||

3. Main Applications of Ceramic Bead Blasting Media

Surface finish for stainless steel products such as outdoor fitness equipments,shelfs,kitchen ware...

Surface balsting for the inner & outter wall of metal pipes

Surface finish for light alloy parts such as aluminum alloy,magnesium alloy,titanium alloy etc.

Surface preparation before elecropalting,anodizing to increase the surface toughness...

4. Abrasion rate comparation between ceramic beads and glass beads

Here is one actual example from our client who use 7mts glass beads one month to blast the die-cast aluminum parts,then

for the same condition,it only used 0.1mts ceramic beads monthly.Then the abrasion rate between ceramic beads and glass

beads is up to 70:1.

It not only reduce the blasting cost but also reduce the treatment cost of solid-waste greatly.

So ceramic beads is more economic blasting media in long term budget if people know that above abrasion rate comparation.

5. Where ceramic beads can replace galss beads?

Generally speaking,ceramic beads can replace glass beads in metal surface blasting completely.

It can also replace ceramic beads where one clean and bright working condition or one lower toughness and brighter blasting

effect are required.

6. Why choose us?

Direct manufacturer of ceramic beads,annual output is over 3000mts;

Equipped with most advanced production line and qualified sales and services teams;

All products can be traced from the very begining of raw materials to the final products.

Stricter quality control system,all the cargo will be sampled beforedelivery even for one small sample.

Prompt delivery and flexible payment term.

Stable suppliers of Foxconn,Samsung Electronics....

|

|

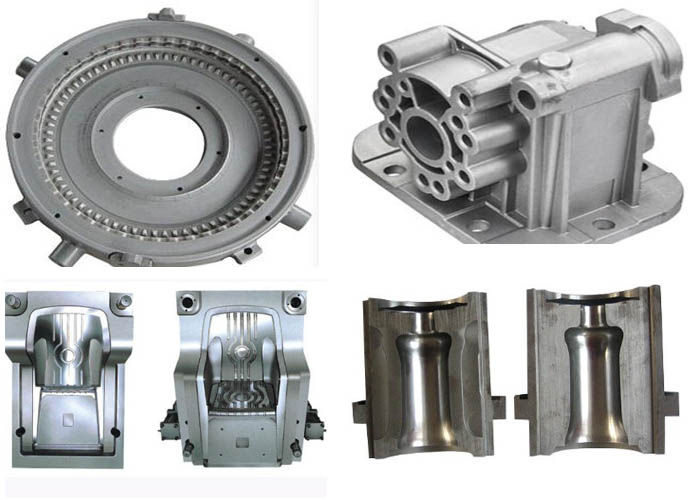

B60 Zirconia Ceramic Bead Blasting For Mold Cleaning Images |